Less Floor Space High Speed Pharmaceutical Alu

Description

Basic Info.

| Model NO. | DPP-260H |

| Customized | Customized |

| Condition | New |

| Warranty | 1 Year |

| Suitable Product | Tablet, Capsule, Softgel, Powder, Liquid |

| Material Feeder | Universal or Dedicated Feeder |

| Forming Type | Flat Type |

| Machine Speed | 20~45 Punches Per Minute |

| Transport Package | Wooden Case |

| Specification | 3500x741x1680mm |

| Trademark | Winwin |

| Origin | China |

| HS Code | 84223030 |

| Production Capacity | 120set/Year |

Product Description

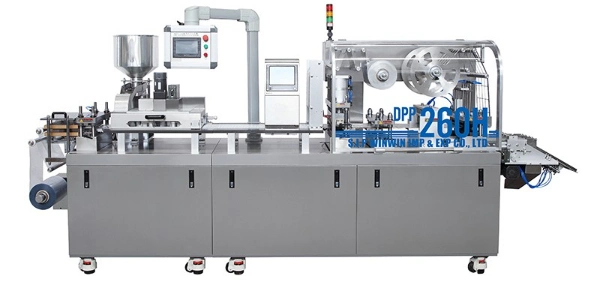

Less floor space high speed pharmaceutical alu-PVC blister packing machine DPP-260H

- Internal mechanical structure

- Electric cabinet and pneumatic control cabinet

- Forming station and quick connection die

- Universal feeder and outlet conveyor

This high speed Alu-PVC blister packing machine integrates light, machinery, electricity and gas, which is controlled by PLC programmable. It can automatically complete the process of forming, feeding, heat sealing and cutting. Applicable to pharmaceutical, food, electronics, medical device, hardware and other industries of aluminum-pvc, paper-aluminum, aluminum-aluminum (by dedicated mould) and other packaging.

1.This machine can realize two kinds of packing methods: aluminum plastic / paper plastic and aluminium and aluminium.

2.This machine is lengthened and adopts split assembly, which is convenient for elevator and cleaning workshop;

3.This machine is lengthened, molding and heat sealing loading station is 1.6m longer, convenient for customer matching special feeder or camera detection system, ensure that the feeding rate and filling rate of finished products.

4.Die with center positioning groove, convenient and rapid replacement; Also can be selected with Aluminum Alloy rail matching with mold, with more convenient adjustment.

5.This machine has increased the cam, can make the bubble maximum depth of 26mm, meet the special requirements of a large pill, medical equipment, food and other industries.

6.This machine transmission is separated from the electrical phase. The stainless steel outer cover is changed into open type for easy operation, maintenance and maintenance.

7.The machine adopts integral arch plane frame, make the machine more precise,firm and durable, avoid cross contamination; All parts in contact with drugs are made of high quality 316 stainless steel and high quality aluminum alloy non-toxic materials , in full compliance with the GMP standard.

8.Customers can choose photoelectric alignment, optical fiber inspection or camera detection device according to requirements.

9.According to customer needs, optional online mode, by increasing the image detecting system (or optical fiber detection system), vacuum suction plate sorting device and conveyor belt etc. reserved line interface, can be directly with the pillow machine, cartoning machine and other equipment such as linkage automatic production line.

| Model | DPP-260H |

| Cutting Frequency | For special designed Alu-PVC: 20-30 times/min |

| Production Capacity | For special designed Alu-PVC: 8,400-12,600 pc/hr |

| Max Forming Depth | 14mm (can be customized for special requirement) |

| Travel Range | 40-160mm |

| Total Power | 380V/50Hz, main motor 1.5kW, hot-sealing 4.5kW |

| PVC Sheet | 0.15-0.45×260 mm |

| PTP Aluminum Foil | 0.02-0.03 ×260 mm |

| Cooling | Tap water or recycling chilled water consumption 60L/H |

| Compressed air | ≥0.2m3/min |

| Overall Dimensions | 3500(L) × 741(W) × 1680(H)mm |

| Weight | 2000kg |

Packaging & Shipping

Standard packaging is wooden case with dust and moisture proof.

Machine can be shipped by sea at lower freight cost.

Machine can also be shipped by train for quick delivery.

Our Advantages

Trusted by hundreds of customers in over 40 countries, we're confident to meet your critical requirements too.

Next: Medical & Pharmaceutical Disposable Syringe /Vial /Ampoule Blister Packing and Cartoning Machine

Our Contact